Part 1: Defining project scope & goals…

In the beginning … of an aerosol product development (PD) project, it is crucial to gather as much information as possible to understand the scope more accurately and to establish reasonable expectations and goals among the team members. The PD team must use the skills of a good investigator to gather as much information as possible by asking questions such as:

• Who is the customer? The intended end user should not be considered the only customer. The “customer” may also include the production department, marketing and sales group, supply chain and logistics managers, and even the formulation chemist who comes up with an idea for a new or improved product. All of these people should be considered “customers” who expect a final product that meets their unique requirements.

• What are you selling? What are the projected sales volumes? What are the minimum order quantities (MOQ)? What do you want on the product label? Will this include third-party evaluations/certifications such as Safer Choice, NSF, Green Seal, and/or U.S. Dept. of Agriculture (USDA) BioPreferred certifications and logos? Are there any statements not wanted on the product label, such as Proposition 65 declarations, flammable or poison warnings, etc.?

• Where are you selling the product? Important locations and market categories to consider include domestic or international, retail or non-retail, and/or States where volatile organic compounds (VOCs) and/or chemicals are restricted or banned.

• When do you want the product? Will the development process be completed, and the finished product delivered, before the anticipated launch date?

• Why is this product important? Marketing research/surveys will provide insight into the practicality of developing and launching the product.

• How is the product to be used? If possible, visit the type of facility where the product will be used and perform end-user field trials.

Embracing a thorough understanding of the customer’s needs requires listening to their responses without bias and making sure that everyone on the development team is speaking the same language. Communicating and documenting accurate and current information between the appropriate parties throughout the project timeline will help ensure that the final deliverable meets everyone’s expectations in a timely and cost-effective manner.

Acquiring information

When searching for information on aerosol product formulas, there are a multitude of resources available. Trade organizations—such as the Southern Aerosol Technical Association (SATA), Western Aerosol Information Bureau (WAIB), Eastern Aerosol Association (EAA), Midwest Aerosol Association (MAA) and National Aerosol Association (NAA)—provide valuable information on the industry, including regulatory updates, industry news and events. The Aerosol Handbook by Montfort A. Johnsen is an invaluable reference volume for all things aerosol, from aerosol measurements to Zinc-rich coatings. Trade magazines, such as the one you are currently reading, offer information on the latest trends, products, testing practices and formularies that can help to efficiently develop your formula.

Additionally, component and chemical vendors are always willing and able to provide valuable literature on the function and properties of product components. This includes providing documents such as the chemical safety data sheets (SDS), technical data sheets, component specifications and any relevant regulatory information. The internet is also a great source of information, with materials and ingredients search engines such as ChemSpider, SpecialChem and UL Prospector providing access to information on product ingredients, regulatory compliance and competitor pricing. Wikipedia can also be a useful source of information, although it should be used with caution as it may not always be reliable. Finally, evaluating comparable product samples will provide valuable insights into the formulation of different product classes.

Determining project limitations

When developing aerosol products, it is important to consider the various resource limitations that can impact the project’s success. These include the desired product performance, project duration and hours set aside for the project, cost of the finished product, product complexity, the capabilities and limitations of the production unit, chemical and component cost and availability evaluation, regulatory constraints, quality control requirements and potential patent infringement issues.

The expected product performance, the duration and hours delegated to the project, and the cost of the finished product, will have an impact on the project’s budget and timeline, as well as the product’s success, profitability and competitiveness in the market. Performance, time and cost all exert competing pressure on the available project development resources. A decision regarding which of these has a high, medium or low priority should be made early in the development process.

Marketing surveys & field testing

Market surveys and field testing play a crucial role in shaping the development of a product. They both empower businesses to make informed decisions, tailor products to customer needs and enhance overall success. Marketing surveys can uncover information about user preferences, pain points and unmet needs, as well as gauge how much customers are willing to pay for a product. Field testing allows products to be evaluated outside of the controlled laboratory environment, exposing them to diverse conditions, different environments, user behaviors and unexpected challenges. It also identifies potential hazards, ensuring that the product doesn’t pose risks to users or the environment.

Product complexity

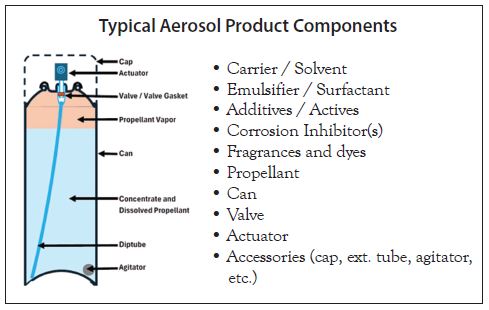

The figure below displays what could be considered “typical” aerosol product components. Each of these has a particular cost, a MOQ and supply chain lead time that will impact the project timeline, budget and feasibility. Also, developing new, innovative components will dramatically increase the project timeline due to the additional planning and testing required, as well as to ensure the component(s) will meet performance and safety expectations. Because of this, it is a good idea to minimize component complexity to that which is necessary and consistent with the project goals and customer expectations.

Production facility capabilities & safety considerations

Formula development must consider the capability of the manufacturing production equipment and personnel. Consider the size, power and types of mixing equipment available to your compounding unit. Also, make sure your compounding personnel have the training and expertise to scale up the batching process from the lab to the plant. If either the equipment or personnel are lacking, either the formula must be adjusted not to exceed the capabilities of the manufacturing unit, or the capabilities of the equipment and personnel must be upgraded. Such upgrades can be quite expensive, so this information must be incorporated into the overall project feasibility equation. Additional manufacturing capabilities and limitations to consider when developing the product formula include workplace ventilation systems, grounding and spark suppression equipment, temperature control capabilities for chemical storage and batch processing, gas house capabilities and the storage/removal of hazardous waste. Ignoring any of these can have a detrimental impact on the safety, quality and productivity of the manufacturing process.

Always remember, you will be working with highly flammable, toxic and/or explosive chemicals/gases. Each day you potentially put yourself and your co-workers in danger. Make safety your first priority!

The Quoting Process: Product cost, availability & MOQ

To provide the customer with a realistic quoted price, lead time estimate and MOQ for a product, the PD team must consider the cost, availability, MOQ and lead time of each individual chemical and component of the said product.

The formulation chemist and/or packaging engineer can work together to consolidate chemical and component inventories. Consolidating materials that are functional equivalents can take advantage of high-volume discounts from vendors and reduce warehouse inventory pressures. This strategy is particularly useful in reducing the overall cost and MOQ issues for solvents, propellants and valves.

Manufacturing efficiency can be improved, and production cost decreased, by reducing production line downtime due to the product changeover process. Cost reductions can be achieved by formulating products so that line and equipment flushing duration and the cost/volume of cleanout solvents are decreased. This also reduces the need to store and dispose of excessive hazardous materials generated during the cleaning process. The cost of increased line cleaning complexity and/or of adding dedicated equipment to the production process should be incorporated into the overall cost of the final product.

QC requirements

Quality control (QC) is essential for ensuring product quality and preventing defects. However, if not managed properly, it can lead to increased manufacturing costs and delays. The PD and manufacturing teams need to work together to determine the quality assurance/quality control (QA/QC) practices necessary to consistently deliver a final product that meets the customer’s expectations.

Generating QC specifications that the production team cannot achieve, due to equipment or personnel limitations, will inevitably lead to defective items, wasted materials and increased labor costs. On the other hand, inadequate QC overview will result in similar consequences—with the added cost of losing the trust of the customer due to inferior products arriving at their facility. It is important to find the appropriate level of QC to prevent product defects while eliminating the cost of a prolonged QC process, unnecessary testing equipment and excess laboratory labor.

Regulatory compliance

Ensuring regulatory compliance is arguably the biggest challenge faced by the PD team. Aerosols are one of the most heavily regulated products due to their environmental impact and potential health risks. As a result, there are a multitude of regulations that aim to control their use, minimize VOC emissions and protect both human health and the environment. These regulations include:

• Federal, State and regional VOC/ Maximum Incremental Reactivity (MIR) regulations

• Federal, State and local chemical restrictions/bans

• California Proposition 65 cancer and reproductive harm warnings

• CA SB-258 and New York State Dept. of Environmental Conservation (NYDEC) ingredient disclosure requirements

• U.S. Environmental Protection Agency (EPA) and U.S. Food & Drug Administration (FDA) product registration and labeling requirements

• Consumer product labeling requirements

• U.S. Dept. of Transportation (DOT) and U.S. Occupational Safety & Health Administration (OSHA) hazard communication requirements

• National Fire Protection Association (NFPA) aerosol storage requirements

• And many more…

Attempting to comply with the various regulations will often have an impact by lengthening the project’s timeline and dampening expectations of what is possible to achieve as a final objective.

Patent infringement

Patent infringement is another constraint that must be considered, as it can have an impact on the project’s legal status and profitability. To avoid patent infringement issues, it is important to take several steps. First, look for relevant patents related to your product. Second, review the claims of those patents that you found. Third, modify your product design around those patent claims. Trademarking your brand’s names and logos, as well as applying for design and utility patents for each product, can help protect your intellectual property.

In a nutshell

It is the responsibility of the PD team to ensure that the final product is delivered in a safe, timely and cost-effective manner while meeting or exceeding the expectations of the customer. The most important part of this process is promptly providing accurate information and status updates to all project stakeholders. Secondary roles that may alleviate unnecessary stress and avoid unpleasant surprises include managing expectations, maintaining focus and accepting that there may be changes in the project goals based on new information. While the challenges the team will face are significant, the reward of a satisfied customer, a job well done and the bragging rights gained when friends and family see one of “your” products on store shelves certainly make the struggle worthwhile.

Part Two of this article will focus on the testing performed on aerosol products and how the results can be interpreted to improve product performance. Part Three will focus on the typical aerosol product laboratory setup, equipment and safety considerations. SPRAY