Written on: May 1, 2023 by W. Stephen Tait

Hello, everyone. This month, I’m starting a two-part series on the roles that water plays in causing or contributing to spray package corrosion. Water is in a formula as either an ingredient or a contaminant.

Steel alloys and aluminum alloys are both used to fabricate spray packages with and without coatings or laminate films. Steel alloys are in sheets and aluminum alloys can be either thin solid plugs (about the size of an ice hockey puck) or thin foils.

Water and metals are both thermodynamically unstable when in contact with each other. Thus, water can cause or contribute to package metal corrosion.

Water is a useful ingredient in a formula because it dissolves a wide range of other formula ingredients and also dissolves into a wide range of formula chemicals, solvents and propellants. For example, inorganic and organic salts, such as sodium chloride or sodium benzoate, dissolve in water.

Most gases dissolve in water, and some of these gases—such as carbon dioxide—react with water to form corrosive carbonic acid. Dimethyl ether (DME) propellant is water-soluble and small amounts of water will dissolve in HFC152a propellant, liquefied petroleum gas (LPG) propellants and most organic solvents.

Water and surfactants are used to form emulsions with water-insoluble ingredients. Emulsions can be either water in oil (oil-out or W/O emulsions), or oil in water (water-out or O/W emulsions).

Consequently, water is both a solvent and, in some instances, a corrosive species.

Water chemistry & properties

You probably remember from your first chemistry course that water molecules have one oxygen atom bonded to two hydrogen atoms (H2O). The valence electrons in water molecules are not shared equally between the hydrogen and oxygen atoms. Thus, one area of the water molecule is positively charged (the hydrogen end) and the other area is negatively charged (the oxygen end). The positive end is attracted to the negative charge associated with surface metal atom valence electrons.

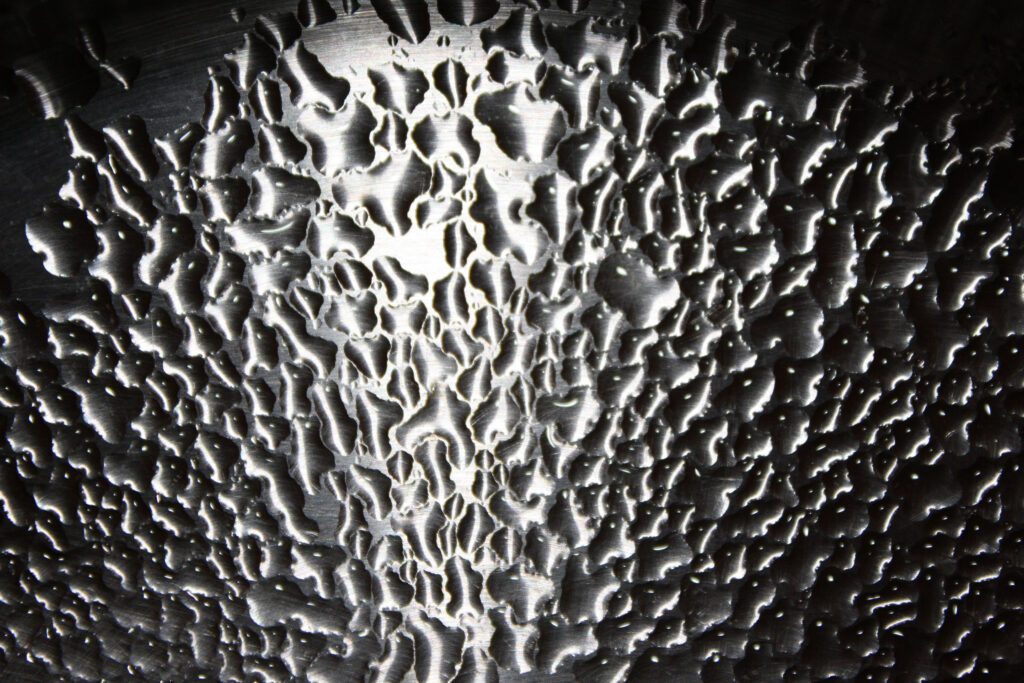

Water’s small size also allows it to absorb into and migrate through interior package coatings and laminate films. Polymers swell when water absorbs into and diffuses through a polymer, thereby creating microscopic rivers through both polymer coatings and laminate films. Microscopic rivers that terminate at the package metal can cause both metal corrosion and polymer delamination, such as blisters.

Water & spray package corrosion

There is an approximate 62% probability of package-metal corrosion whenever corrosion testing is not conducted. Water molecules are electrochemically active, but water also dissociates into electrochemically active hydrogen ions and hydroxyl ions. Electrochemically active water and dissociated hydrogen ions can both remove electrons from spray package metals, thereby causing corrosion. In other words, in addition to being a solvent, water is also potentially a corrosive ingredient or contaminant.

Liquid-water plays multiple roles in a formula and in package material corrosion (more on liquid-water in the next issue). Water’s various corrosion roles are it:

• Could be a corrosive formula ingredient

• Transports corrosive formula ingredients to the package metal

• Moves ions to/from corrosion sites to maintain the electrical balance between the corrosion sites and their surrounding areas

• Hydrates metal ions formed by corrosion

• Provides hydroxyl ions that bond with metal ions, forming visible corrosion, such as the various colors of rust observed on steel or the white and black corrosion on aluminum

• Migrates through package polymer coatings and laminate films to the package metal to cause metal corrosion and/or coating/laminate film corrosion, such as blistering

• Transforms coatings/laminate films into semi-permeable membranes that allow only specific formula ingredients to migrate through the coating/film to the package-metal

• Forms microscopic rivers of formula ingredients in a container coating or laminate film that could subsequently cause coating delamination and/or metal corrosion

• Is a solvent for the various corrosion inhibitors used to prevent and control spray package corrosion

Next time, we’ll discuss the mechanism for water corrosion and how water supports pitting corrosion, as well as how much water is needed to initiate spray package corrosion.

Thanks for your interest and I’ll see you in June. Contact me at 608-831-2076; rustdr@pairodocspro.com or from our two websites: pairodocspro.com and aristartec.com. SPRAY